Turbine flow rate monitoring

Reliable principles must be applied when measuring flow in pipes under load in hydroelectric power plants, because of the economic and safety challenges posed by penstocks.

This operation relates to four penstocks, 7.4m in diameter, situated in a hydroelectric power plant in South Africa. The measurement system installed by Ultraflux uses clamp-on probes to regulate the plant’s flows and protect against the risk of flooding in the valley.

Before making a commitment to providing a solution and finding the expected results, Ultraflux requested an acoustic transmission test in order to confirm the internal state of the pipe and the absence of trapped air. This type of test, which we think should be systematic, was carried out using a portable flow meter and SE 1599 probes in direct configuration.

| FLOW METERS | |

| Uf 821 converter | SE 1599 clamp-on probes |

|

|

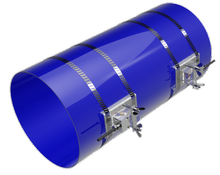

| Uf 821 | In order to strengthen the ultrasound signals observed during the preliminary tests, we suggested twin SE 1599-I sensors, which provide an extra 16 dB. A special support was designed for attachment without straps. Only one cable is needed per set of twin probes. In order to better monitor the scope of output speeds and to obtain a backup measurement in the event of failure, we installed two direct diametric chords. |

The maximum flow per group is 160 m3/s, i.e., depending on the TDH, a power per group of around 100 MW. On the basis of the turbine and generator qualification tests, the precision of the four flow measurements was confirmed to be +/- 1 %.

The advantages of our installation, in addition to its precision, are the absence of moving parts and a lack of heavy-duty work, such as drilling, which is forbidden for safety reasons.