Detection of spheres in the pipelines

In order to prepare for the introduction of scrapers, spheres or other “pigs” into pipelines, manufacturers often use mechanical sensors. These sensors react when the element they are designed to detect comes into contact with them.

There are several disadvantages to this method:

- High installation cost (shut-down of the process and drilling into the pipe, etc.),

- Product is in contact with the fluid,

- Frequent maintenance is required due to the ongoing collisions,

- Breakage risk for the sensor, the sphere and the scraper.

This issue affects companies that produce or ship hydrocarbons:

- Refineries,

- Hydrocarbon transportation companies,

- Oil rigs,

- Engineering firms, etc.

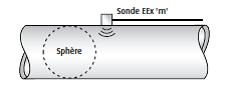

The probe is installed on the outside of the pipe and attached using a support wrapped around the pipe. It sends out a steady ultrasound beam.

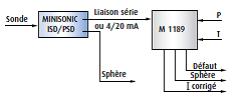

When a foreign body or a liquid cuts through this beam for a certain period of time, it is recognised as a scraper, a sphere or any other targeted object. The information can then be transmitted to a PLC, for example via a 4-20mA or RS232 output or via a relay, etc.

Several products may be suggested for the converter:

- Minisonic PSD: detector* with standard metal casing,

- Portable Minisonic PSD: Portable detector*,

- Minisonic PSD G: detector* adapted for gas applications,

- Minisonic PSD rack: detector* with a rack-type casing,

- Minisonic PSD EX: detector* in an explosion-proof box,

- Minisonic PSD G EX: detector for gas applications in an explosion-proof box.

*of sphere or scraper

Boîtier standard |

Coffret antidéflagrant |

Three probes may be offered depending on the applications and diameters:

- SXN 1524,

- SXN 1679,

- SXN 1691.

These probes are developed and manufactured in compliance with ATEX Standards and are Ex m II T6 certified.

Detection of spheres, even adjoining spheres, with:

- Response time of < 1 s,

- High measurement rate,

- A log of the time and date of the last 20 scrapers or spheres that can be viewed using a PC,

- Transmission of information

- Digital RS 232 et 485 – Protocol JBUS/MODBUS,

- Current output 4-20 mA/1000 Ohms – integrated galvanic isolator,

- Two solid-state relays – 100 V/100 mA/10 VA maxi.

The ultrasound technology of the Minisonic PSD responds to all of the problems raised by those working in the sector, mainly due to:

- A low installation cost (the use of “clamp-on” probes means that processes do not have to be shut down for the installation and no holes are made in the pipe. The installation takes half a day).

- No contact between the probe and the fluid (the use of clamp-on probes protects the fluid and does not disrupt the flow).

- No or little maintenance required (the installation of clamp-on probes avoids rubbing and premature wear).

- No breakage risk for the sensor, sphere or scraper (no contact and so no risk of breakage).

- The device can be placed in an ATEX zone (only allowed where an explosion-proof box has been chosen).